Kunezinkulungwane zezizathu zokuthi ipayipi le-hydraulic lingahluleka, kodwa ngokuvamile, ukwehluleka okuvame kakhulu bekungagwenywa ngezinyathelo ezifanele zokuphepha. Kusukela namuhla futhi kusukela manje, Sizokwethula izizathu eziyisishiyagalombili ezivame kakhulu zokuhluleka kwepayipi nokuthi singazivikela kanjani kuzo, Namuhla sizokwethula esinye sezizathu ezibangela ukwehluleka kwepayipi le-hydraulic.

1. Kweshubhu LethumbuErosion

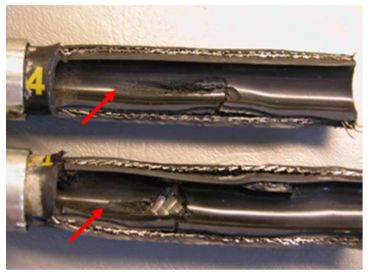

Ukuguguleka kwepayipi le-Hydraulic hose kuvame ukudala ukuvuza kwangaphandle, okuyinkinga enkulu yokusebenza okujwayelekile kwe-hydraulic hose. Ukuguguleka kweshubhu kuvame ukubangelwa uketshezi olunesivinini esiphezulu esigxilile noma izinhlayiya ezincane oketshezini. Imicibisholo ebomvu esesithombeni ikhomba ekuqaleni kokuguguleka.

Ukuze ugweme ukuguguleka kweshubhu, sebenzisa i-Hose Products Division's flow capacity nomogram ukuze unqume usayizi wepayipi ofanele ngokusekelwe kumthamo wesivinini onconywayo. Futhi, qiniseka ukuthi ukuhlanganiswa kwepayipi akugobile kakhulu ukuze kugeleze nokuthi i-fluid medium ayibi kakhulu ishubhu elingaphakathi lepayipi. Kubalulekile ukulandela i-radius ephezulu yokugoba ephawulwe ekucacisweni kobunjiniyela kwepayipi ngalinye, kanye nobubanzi, phakathi nenqubo yokuhlanganisa.

Ngemva kokuthenga ipayipi le-hydraulic hose R1AT R2AT 1SC 2SC 4SH 4SP 1ST 2ST njll ipayipi le-hydraulic, uma kunokungabaza mayelana ne-hydraulic hose bend radius yethu, Sicela ukhululeke ukuxhumana nathi. Umdayisi wethu kanye Nonjiniyela bazokunikeza idatha yethu yepayipi le-hydraulic ukuze wenze ukuhlanganiswa kwepayipi ngendlela efanele. Singanikeza ukwesekwa kwezobuchwepheshe ekusebenzeni kwepayipi le-hydraulic kanye nokuhlanganiswa kwepayipi. Ngoba sinonjiniyela abaphezulu. Mayelana nama-hydraulic hoses, Imvamisa ikhasimende lethu linolwazi oluhle lokusebenzisa, futhi uma uthanda, sicela usithinte ngokuqondile, siyajabula ukwabelana nawe ngomkhiqizo wethu wokuthengisa oshisayo, kanye nokwesekwa kochwepheshe emakethe yakho ye-hose.

I-Att1 Amandla Okugeleza Kumajubane Okugeleza Anconyiwe

2. Ukuhambisana noketshezi

Akuwona wonke uketshezi kanye namapayipi amanzi ahambisanayo. Uma uketshezi olungahambelani lusetshenziswa ngepayipi lekhwalithi engcono kakhulu, lungabangela ipayipi ukuthi liqale ukuhlakazeka ngaphakathi, livuvuke, futhi linciphe. Uma ipayipi lihlakazeka futhi livuza, kungenzeka ukungcoliswa kwezinhlayiyana ezimbi kakhulu ohlelweni lwe-hydraulic.

Qinisekisa ukuthi wonke amapayipi amanzi asetshenziswayo ahambisana noketshezi olugeleza kuwo.

Ipayipi oli-oda kufanele lihambisane noketshezi oludluliswayo. Qinisekisa ukuthi uketshezi aluhambisani kuphela neshubhu elingaphakathi, kodwa futhi ikhava yangaphandle, okokufakwayo, ngisho nama-O-rings. Ukuqinisekisa ukuthi imidiya yakho iyahambisana

I-Att2 Hlola ishadi lepayipi lokumelana namakhemikhali

3. Igesi eyomile / Igesi eyomile

Ishubhu elingaphakathi lamapayipi lingadala imifantu emincane eminingi ngenxa yegesi elidala noma elomile. Lolu hlobo lokwehluleka kwesinye isikhathi kunzima ukulubona ngoba ipayipi lizohlala liguquguquka, nokho kuzoba nezimpawu zokuvuza kwangaphandle. Ngokuvamile, azikho izimpawu zokuqhekeka kwe-hose ngaphansi kokufakwa.

Ukuze ugweme izinkinga zomoya owomile noma ezindala, qinisekisa ukuthi ipayipi lakho likalelwe umoya owomile kakhulu. Amapayipi anamashubhu angaphakathi enjoloba ye-PKR noma ye-EPDM ayakhethwa kulezi zinhlelo zokusebenza.Noma hlaba iphini kurabha yekhava.

4. Ukuhuzuka

Amapayipi asetshenziswa yi-hydraulic asetshenziswa kanzima nsuku zonke, agcine eseba nomthelela omubi. Uma kungahlolisiswa njalo, ukuhuzuka kungabangela ukuqhuma kwepayipi nokuvuza. Ukuhlikihlwa kwepayipi ngokweqile entweni engaphandle noma enye ipayipi kungaguga ikhava futhi ekugcineni kube nezingqimba zokuqinisa.

Isembozo senzelwe ukuvikela ipayipi, ngakho izimpawu zokulimala kwesembozo noma izendlalelo zokuqinisa kufanele zikuxwayise ukuthi kukhona okungalungile.

Ukuze kuncishiswe ukuhuzuka, amanye amapayipi anezinsimbi zepulasitiki ezifakwa ezintweni ezakha ikhava yepayipi. Uma kunezindawo ezithize eziyinkinga, unogada wepulasitiki noma umkhono wenayiloni ungasetshenziswa ukuvikela ipayipi.

5. Amazinga Okushisa aphezulu kanye Nokuguga Kokushisa

Lapho amapayipi evezwa emazingeni okushisa aphezulu, aqala ukulahlekelwa ukuguquguquka kwawo futhi aqine. Amazinga okushisa aphezulu abangela ukuba ama-plasticizer akushubhu yangaphakathi ye-elastomeric aphuke, abe eseqina futhi aqale ukuqhekeka. Ngokuhamba kwesikhathi, leyo mifantu ingagcina ifinyelele ngaphandle kwepayipi. Uma ususa ipayipi futhi lenza umsindo wokuqhekeka lapho uligoba noma uma lihlala lisesimweni esigobile, khona-ke inkinga ukushisa ukuguga.

Ukuze unciphise imithelela yokuguga kokushisa, gwema ukusebenzisa amapayipi ngokungenasidingo ezindaweni zokushisa okuphezulu futhi uqinisekise ukuthi amapayipi alinganiselwe izinga lokushisa elifanele eliqhubekayo lokusebenza. Uma ukuchayeka kokushisa kungenakugwenywa, cabangela ukusetshenziswa kweziqaphi zokushisa phezu kwamapayipi.

6. Ibanga elincane lokugoba

Sicela unake kakhulu irediyasi yokugoba , ukuze ugweme izinkinga ze-hydraulic hose kinking.

Ama-hose assemblies angahluleka ngokushesha uma kuhlangatshezwana ne-radius yokugoba encane. Kulesi sithombe, kusobala ukuthi ishubhu nekhava kuqhekezwe ngaphandle kokugoba, okuphawulwe umcibisholo obomvu. Indingilizi eluhlaza okwesibhakabhaka ikhombisa lapho ishubhu nekhava kuboshwe khona ngaphakathi kokugoba.

Ezicelweni ze-vacuum noma zokumunca, uma i-radius egobile yeqiwe, ipayipi ingase ibe isicaba endaweni yokugoba. Lokhu kuzovimbela noma kukhawulele ukugeleza. Uma ukugoba kuqine ngokwanele, i-hose ingase ikhabe. Ukuze uvimbele ukwehluleka okuncane kwepayipi lerediyasi egobile, hlola kabili irediyasi enconyiwe yokugoba. Shintshanisa amapayipi futhi ushintshe umzila, ubude, noma okokufaka ukuze uhambise ipayipi ngaphakathi kwerediyasi yokugoba eshicilelwe uma ingathobeli.

7. Umhlangano Ongalungile

Uma ukuhlanganiswa kwepayipi kungahlanganiswa kahle, kungadala izimo eziyingozi kakhulu.

Lapho amapayipi esikwa ngosayizi, kufanele ahlanzwe ngokucophelela futhi ashaywe ukuze avimbele ukungcoliswa yimfucumfucu eqhumayo esele. Ishubhu elingaphakathi kufanele lihlanzeke ngangokunokwenzeka, futhi iziphetho zamapayipi kufanele ziboshwe ngemuva kokuthi izinsimbi ziboshwe endaweni.

Ukufakwa kumele kuphushwe ngokuphelele ukuze kuhlangatshezwane nokujula kokufakwa okunconyiwe. Uma ukujula kokufakwa kwe-hose kungafinyelelwanga, okokufaka kungaphephuka, kushiye ukuhlanganiswa kwepayipi elihlulekile. Ukubamba kokugcina kugobolondo elifanelekile kubalulekile emandleni okubamba.

8.Po noma Umzila

Enye imbangela enkulu yokuhluleka kwepayipi le-hydraulic ukungahambi kahle komzila. Gwema ukuhambisa ipayipi endaweni engase ibe nemihuzuko noma iphoyinti le-pivot. Ungawahambisi amapayipi ezindaweni ezishisayo ngaphandle uma ingekho enye indlela. Nakisisa ukuthi i-radius encane yokugoba iyafinyelelwa ukuze ugweme ukugoqa, ama-kinks, nokwehluleka.

Uma i-hose ingase ibe ngaphansi kokunyakaza okuningi, cabangela ukusetshenziswa kwe-swivel ekugcineni kwayo. Ngamafuphi, sebenzisa eminye imizila, amapayipi amade, noma ukufakwa okuhlukile njengoba kudingeka futhi uhlele umzila ozobangela inani elincane lokuhuzuka noma ukugoba.

Isikhathi sokuthumela: Mar-16-2023