There are thousands of reasons a hydraulic hose can fail, but often, the most common failures could have been avoided with proper precautions. From today and since, We are going to introduce eight of the most common reasons for hose failure and how to protect against them, Today we are going to introduce one of reason cause hydraulic hose failure.

1. Hose Tube Erosion

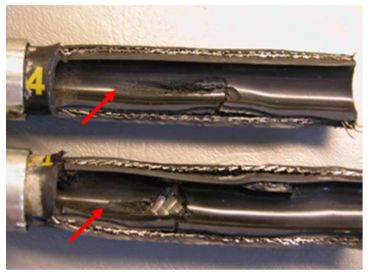

Hydraulic hose tube erosion often causes external leakage, which is a big problem for hydraulic hose normal working. Tube erosion is usually caused by a concentrated high-velocity stream of fluid or by small particles in the fluid. The red arrows in the image point to the start of the erosion.

In order to avoid tube erosion, use Hose Products Division’s flow capacity nomogram to determine the proper hose size based on the recommended maximum velocities. Also, be sure that the hose assembly is not bent too tight for flow and that the fluid medium is not too abrasive for the inner tube of the hose. It is important to follow the maximum bend radius noted in the engineering specifications for each hose, as well as diameter, during the assembly process.

After you purchased hydraulic hose R1AT R2AT 1SC 2SC 4SH 4SP 1ST 2ST etc hydraulic hose, uf there is doubt about our hydraulic hose bend radius, Please feel free to contact us. Our salesman and Engineers will give our hydraulic hose data for you to make hose assembly in right way. We can give technical support on hydraulic hose operation and hose assembly. Because we have top engineers. Regarding hydraulic hoses, Usually our customer have good usage experiences, and if you are interested, please contact us directly, we are glad to share our hot sale product with you, and professional support on your hose market.

Att1 Flow Capacities at Recommended Flow Velocities

2. Fluid compatibility

Not all fluids and hydraulic hoses are compatible. If an incompatible fluid is used with an otherwise excellent quality hose, it can cause the hose to begin to disintegrate from the inside, swell, and delaminate. If the hose disintegrates and leaks, serious particulate contamination to the hydraulic system can occur.

Make sure that all hydraulic hoses in use are compatible with the fluids running through them.

The hose you order must be compatible with the fluid being conveyed. Verify that the fluid is not only compatible with the inner tube, but also the outer cover, fittings, and even O-rings. To ensure that your medium is compatible

Att2 Check hose’s chemical resistance chart

3. Dry gas / aged gas

The inner tube of hoses can develop numerous tiny cracks due to aged or dry gas. This type of failure is sometimes hard to spot because the hose will remain flexible, however there will be signs of external leakage. Typically, there are no signs of cracking on the hose under the fittings.

To avoid dry or aged air problems, confirm your hose is rated for extremely dry air. Hoses with inner tubes of PKR or EPDM rubber are preferred for these applications.Or make pin prick at cover rubber.

4.Abrasion

Hydraulic hoses are put through rigorous applications every day, which eventually take their toll. If not inspected on a regular basis, abrasion can cause a hose assembly to burst and leak. Excessive rubbing of the hose against an external object or even another hose can wear away the cover and eventually the reinforcement layers.

The cover is meant to protect the hose, so signs of damage to the cover or reinforcement layers should warn you that something is wrong.

To minimize abrasion, some hoses have plasticizers added to the material that makes up the hose cover. If there are specific problem areas, a plastic guard or nylon sleeve can be used to protect the hose.

5.High Temperatures and Heat Aging

When hoses are exposed to extreme temperatures, they begin to lose their flexibility and stiffen. High temperatures cause the plasticizers in the elastomeric inner tube to break down, which then hardens and begins to crack. As time goes by, those cracks can eventually reach the outside of the hose. If you remove a hose and it makes a cracking sound when you bend it or if it remains in a bent shape, then the problem is heat aging.

To minimize the effects of heat aging, avoid unnecessarily running hoses through high temperature areas and verify that the hoses are rated for the appropriate continuous operating temperature. If heat exposure cannot be avoided, consider the use of heat guards over the hoses.

6. Minimum bend radius

Please pay much more attention to the bend radius, to avoid the hydraulic hose kinking problems.

Hose assemblies can fail relatively quickly if the minimum bend radius is not met. In this image, it is obvious that the tube and cover physically ripped apart at the outside of the bend, noted by the red arrow. The blue circle indicates where the tube and cover are buckled at the inside of the bend.

In vacuum or suction applications, if the bend radius is exceeded, the hose may tend to be flat in the bend area. This will hinder or restrict flow. If the bend is severe enough, the hose may kink. To prevent minimum bend radius hose failures, double-check the recommended bend radius. Replace hose assemblies and change routing, length, or fittings to route the hose within the published minimum bend radius if they do not comply.

7.Improper Assembly

When a hose assembly is not properly assembled, it can create very dangerous situations.

When the hoses are cut to size, they must be carefully cleaned and flushed to prevent contamination by abrasive debris that is left behind. The inner tube should be as clean as possible, and the ends of the hoses should be clamped after the fittings have been crimped into place.

Fittings need to be pushed on completely to meet the recommended insertion depth. If the hose insertion depth is not met, fittings can blow off, leaving a failed hose assembly. The last grip in the fitting shell is essential to the holding strength.

8.Poor Routing

Another major cause of hydraulic hose failure is poor routing. Avoid routing a hose through a potentially abrasive area or a pivot point. Do not route hoses through high temperature areas unless there is no alternative. Pay close attention that the minimum bend radius is met to avoid buckling, kinks, and failure.

If the hose is likely to be subject to a considerable amount of movement, consider the use of a swivel on the end of it. In short, use alternate routes, longer hoses, or different fittings as needed and plan the routing that will cause the least amount of abrasions or bends.

Post time: Mar-16-2023